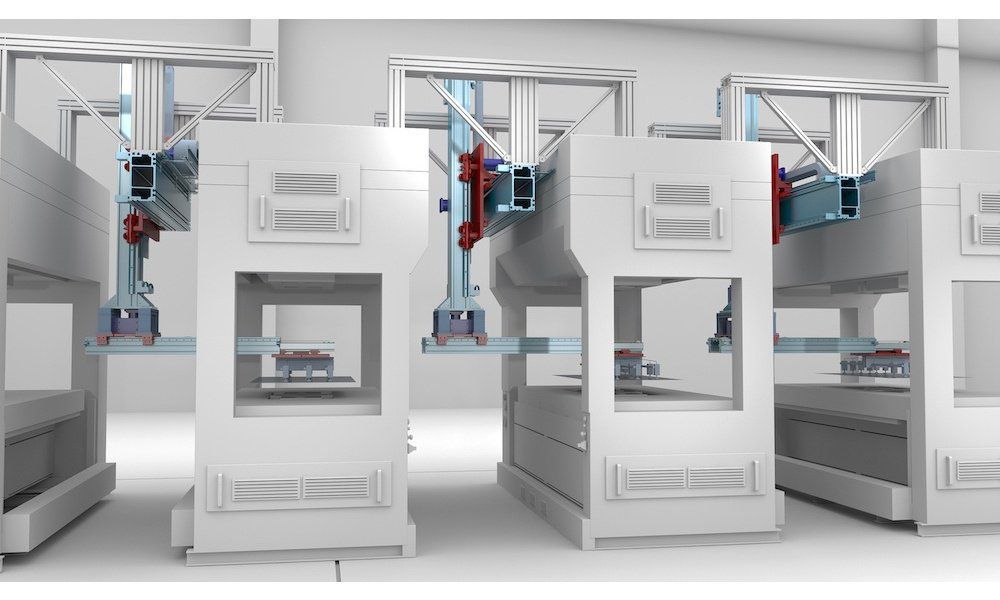

Are you looking for a way to improve the performance and efficiency of your machinery while also saving costs? Look no further than electric actuators! These powerful devices offer a range of benefits that can take your operations to the next level. But what exactly are these benefits, and how can they help you achieve your goals?

First and foremost, electric actuators, such as 8x18nd, provide an advantage over their hydraulic and pneumatic counterparts in that they require less maintenance. Unlike other types of actuators, electric ones do not need fluid or air pressure to operate, which means that there is no need for costly and annoying mechanical maintenance. Moreover, electric actuators are small and easy to integrate into equipment, making them ideal for applications where space is limited.

Another benefit of using electric actuators is the speed and energy savings that they provide. Electric motors can convert electrical power directly into linear motion without the need for screws or other force-converting mechanisms. This eliminates many of the damaging forces associated with mechanical actuation, reducing the likelihood of wounded personnel or damaged equipment.

Additionally, electric actuators offer a high level of precision when it comes to controlling position and movement, making them a popular choice for advanced automation systems. Overall, if you’re looking to improve your machinery’s performance while also saving on costs, consider choosing electric actuators.

Electric actuators have become a popular choice due to their numerous benefits. One of the major advantages is that they are easy to maintain, unlike pneumatic and hydraulic actuators which require frequent maintenance. This low-maintenance feature also makes electric actuators an inexpensive option in the long run.

Another advantage of using electric actuators is that they eliminate many damaging forces associated with mechanical actuation. The use of screws or other force-converting mechanisms can lead to wounded personnel or damaged equipment. With electric motors converting electrical power directly into linear motion, this risk is greatly reduced. Furthermore, electric actuators offer precise control over position and movement, making them an ideal choice for advanced automation systems.

In conclusion, the use of electric actuators of blackhawk supply increases sales by offering significant savings and reliable performance. Their elimination of annoying and costly mechanical maintenance, along with precision in controlling position and movement makes them a chosen equivalent over traditional pneumatic and hydraulic actuators. As technology advances, it’s no surprise that more industries are switching to electric actuators for improved efficiency and productivity.